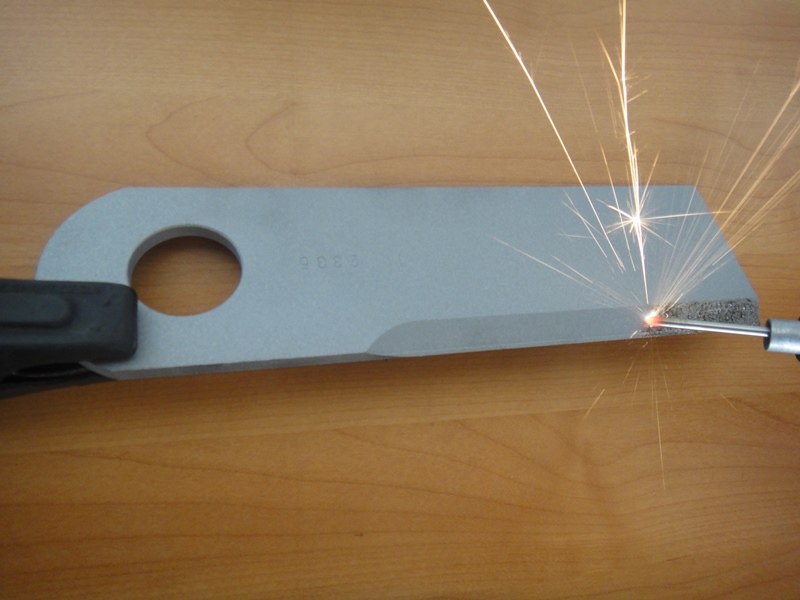

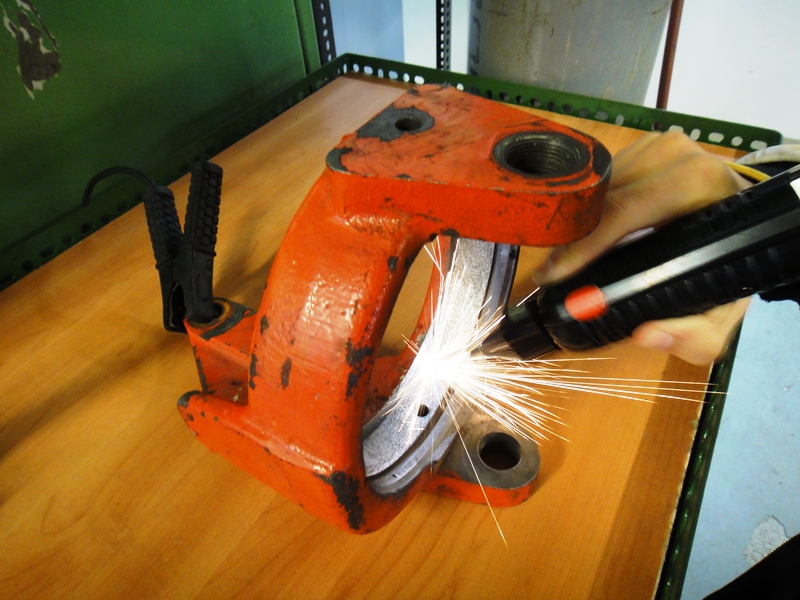

SparkDepo (Electro-Spark Deposition)

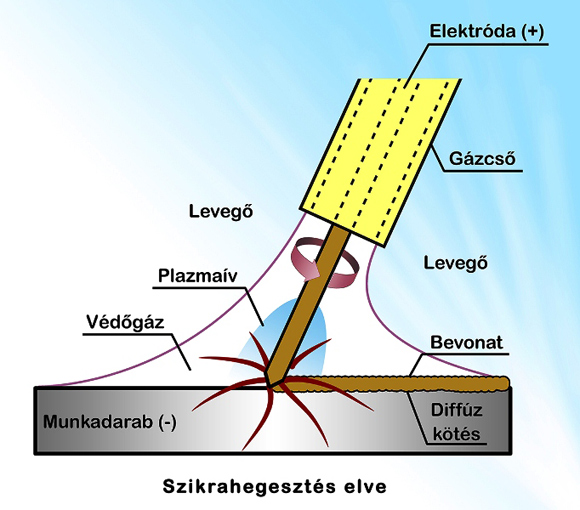

This procedure is common in Japan and in the USA. The owner of the company was trained for usage of the device in Japan, at the manufacturer. In Hungary we are the only ones applying this method in repairs. The SparkDepo process is a revolutionary method of renewing worn surfaces by deposition of wear resistant materials with electric sparks. SparkDepo coatings of tungsten carbide and chromium carbide can prolong the lives of machine parts, dies, molds, and tools that are subjected to wear, heat and corrosion. Thick alloy deposit is also possible for repair and maintenance. Frequent repair and maintenance can be reduced or even eliminated by using SparkDepo, thus increasing productivity or reducing the production cost. SparkDepo is easy to operate, portable, and economical. It can be used on-site and in confined areas. The coating is produced under very low heat input but has a very high bond strength. Direct current from the power supply will heat the electrode to 8,000 to 25,000 degrees C only at the contact areas and transfers a small quantity of the electrode to the work piece under an ionized state and produces a strong metallurgical bonding.