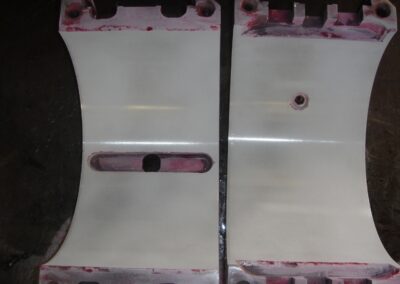

Coating with bearing metal (Babbitt Metal)

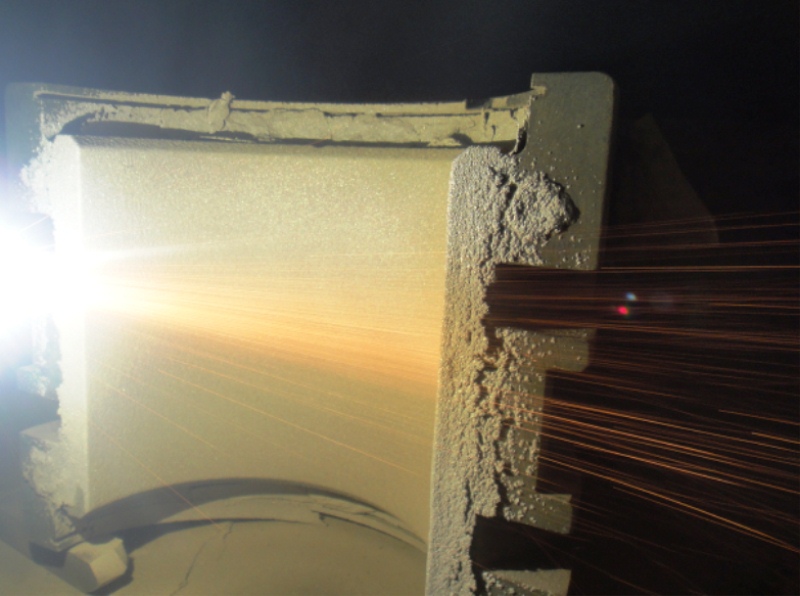

We apply the bearing metal (white metal) with Electric wire (twin wire) arc spray coating, or with the so-called Thermisold (soldering) process in the necessary layer thickness (from 0,5 mm to may 10 mm thickness) onto the surface, which is after cuttable as before and has the same attributes like the layers made with traditional founding. Areas of usage: plain bearings and bearing bushings of turbines, electric power machines, mills, breaking- and disintegrator machines, generators, shiff axles, etc.

Advantages against the traditional founding:

time-saving and cost-effective because of its fast implementation, the downtime reduces

it does not need a lot electric energy, which is – considering today’s energy prices – not negligible

also a very slim layer thickness (even 0,5 mm) is formable

the bearing bushings and bearing sleeves do not deformate and shrink, like during the founding

you do not have to wait for the cooloff, it is immediately workable

Did you know?