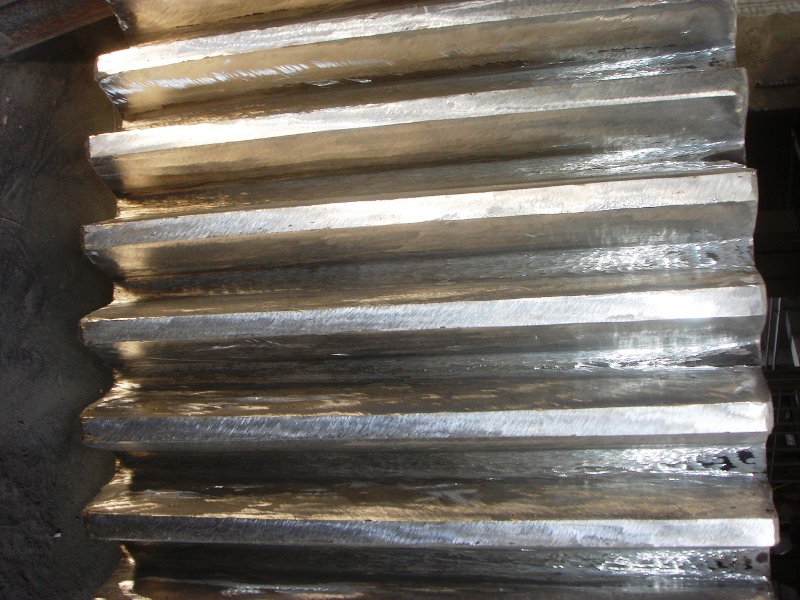

Repair of cog-wheels, racks, and ribbed bindings

We perform the reparation of different worm gears, pulley axles, cogwheels, freewheels, cone-wheels, plate-wheels and ribbed bindings. Wether the cogging has broken off, or it has weared off, we can weld it up with a so-called air-hardening (higher manganese content) material. The raw material can be steel, grey alloy, bronze or aluminium, and the cogging can be straight, inclined or curved. The after-work can be mechanical, but it happens mainly by hands, by a pattern, which is followed by rubbing and polishing. We perform the welding, and the grinding of freewheels of rotating furnaces and mills, also on site.

Advantages of our reparation:

fast, hence the downtime reduced

significantly cheaper than the producion of a new one

often it does not need any fixing, as we perform the reparation also on site, in the machine it is built in

Mixing the reparation with the spark welding we can reach, that the surface of the cog gets a very hard plating (75 HRC), therefore its lifespan will rise.