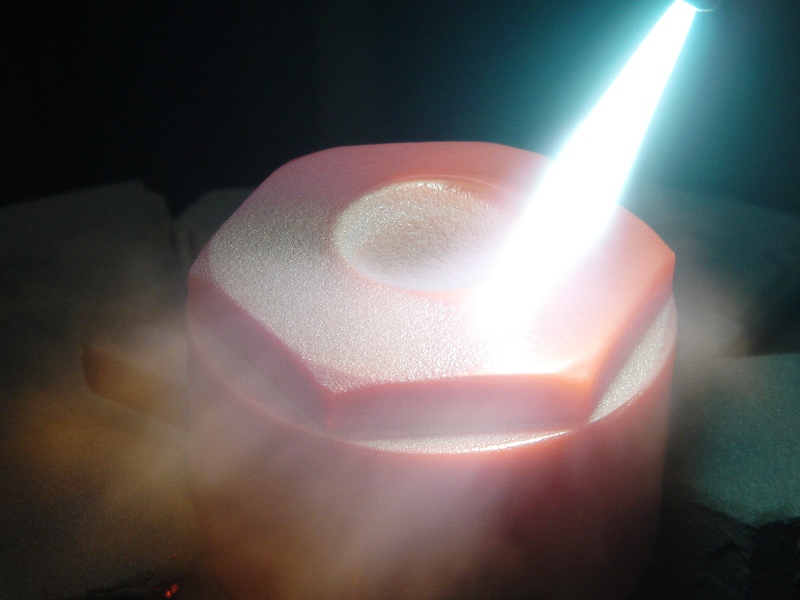

Hot metal spraying

A gas mixture flowing out from a specially designed pistol (jet) and melts the metal powder and injects it onto the designated surface. After reaching the achieving layer thickness, the sprayed layer will be melted and the raw material absorbs into the treated surface.